Metal Detector is an equipment to identify Metal contamination prevalent in food, pharmaceutical and cosmetic products. Metal detectors are traditionally used as a first line of defence in detecting ferrous, non-ferrous and stainless steel contamination in packaged food products, tablets, capsules, soaps, detergents, powdered products, spices, granules, etc. before these products leave the manufacturing / processing plants.

Pharma Metal Detector

Used in Pharmaceutical Industry for detection of metal contamination in tablets and capsules

Combo – Metal Detector + Deduster

Used in Pharma Industry for tablets

Conveyorized Metal Detector

Used to detect metal contamination in packaged products, biscuits, confectionery, soap, etc.

Gravity Feed Metal Detector

Used to detect metal contamination in powder / granules / spices

Metal Detectors

WORKING PRINCIPLE

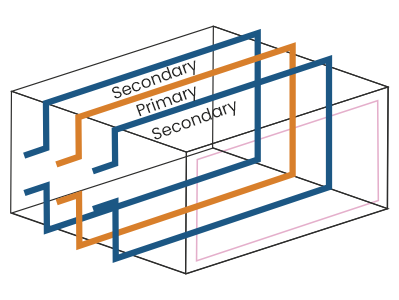

Metal detectors operate by generating electro-magnetic field in the product being tested and analyzing the response to such fields from possible metal contamination. At the heart of a metal detector is a set of coils wound to form an aperture through which the product to be tested is passed. Shown here is a simplified version of such a coil. A primary coil sets up the electromagnetic field at a certain frequency. A secondary coil picks up the response to this field. Any metal particle passing through the coil absorbs energy from the excitation due to eddy currents induced in the metal volume. This minuscule perturbation is picked up by the secondary coils and processed electronically to eventually operate rejection mechanisms.

IMPORTANCE & BENEFITS

Importance of Metal Detector in Food / Pharma Industry

Despite maximum care, metallic contamination in food products during the production process cannot be fully prevented. Metal particles that enter the product during the production process or are already contained in the raw material may cause serious injuries to consumers.

The consequences for the producing company are numerous and serious and include compensation claims and expensive recalls. Even bigger and longer-lasting damage is caused by the negative brand image and the loss of consumer trust caused by contaminated food products.

Benefits of using Industrial Metal Detector

- Detects contamination of Ferrous, Non-Ferrous and Stainless Steel metal particles

- Prevents damage to machinery and production downtime

- Ensures product quality in line with the required standards and certifications

- Protection against customer complaints and recalls

IMPORTANT FEATURES

Digital Signal Processing

Digital signal processing for accurate adjustment of phase angle-To minimize the product effect and get the optimum metal detection sensitivity.

Auto Product Learning

Adjusts the product signal and product threshold automatically. Different settings can be stored in memory for multiple products.

Auto Product Tracking

The machine tracks the product phase to compensate the product variation thereby eliminating chances of false rejection during inline production.

Digital Signal Processing

Digital signal processing for accurate adjustment of phase angle-To minimize the product effect and get the optimum metal detection sensitivity.

E-Signature

Validates the Metal Detector with standard test piece. Standard test pieces are calibrated spherical balls of desired size.

Multi-level Password

Provides safety and control by adding protection layers. Alpha-numeric passwords can be set and rights can be selectively assigned.

Fail Safe Mechanism

Safety interlocks to ensure proper and fail safe separation of metal contaminated product from the good product.

Event Time Stamping

Real Time stamping of event logs available.