A Checkweigher is an automatic dynamic weighing system for checking the weight of a given product. It checks, classifies and rejects Underweight / Overweight products and prevents them from reaching the customer.

Checkweigher uses state of the art technology to achieve greater accuracy in dynamic weighing of products. The system provides 100% online weighing of product ensuring compliance with international standards of Pharmaceutical, Food, Chemical and Cosmetic Industry.

Linear Checkweigher

For weighing in a range of 100gm to 20Kg

Revolving Checkweigher

Typically used for weighing aerosol cans, vials, ampules

Combi-Checker

Combination of Checkweigher and Metal Detector

Shipper Carton Checkweighers

For weighing in a range of 21Kg to 60Kg

Dynamic Checkweigher

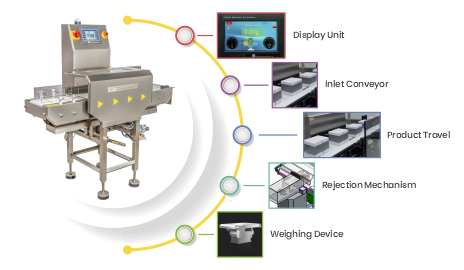

WORKING PRINCIPLE

Product under test gets transfered from the entry conveyor to the weighing conveyor at a set speed. Once the product comes on the weighing conveyor, it exerts pressure on the weighing conveyor and in turn on the load cell.

The load cell takes multiple weight records of the same product before it leaves the weighing conveyor. An average of these multiple weight records is considered as the weight of the product and is displayed on the HMI of the Checkweigher system. If the weight of the product is beyond the set weight limit (overweight or underweight) then the product gets rejected by suitable rejection mechanism on the exit conveyor.

APPLICATIONS OF CHECKWEIGHER

- Check and reject under and / or overweight filled packages

- Check for missing components in a package including labels, instructions, lids, coupons, or products

- Reduce product giveaway by using checkweigher totals to determine filler adjustments

- Classify products into weight grades

- Weight before and after a filling to check process performance

IMPORTANT FEATURES

Standard Features

- Modern graphical user interface

- Auto adjustment of conveyor speed according to throughout speed of incoming product

- Height adjustment for ease of integration with existing lines

- Informative dashboard, multi-weight classification

- Ethernet connectivity

- Multi product memory

- Facility for Dynamic weight compensation

- Display of net weight

- Statistical data of ‘Total Accept’, ‘Total Reject’ and ‘Standard Deviation’

GX Series – Additional Features

- 11.6” display (7” display in standard system)

- FDA 21 CFR Part 11 compliant

- Up to 1000 product recipe

- Inbuilt report generation in PDF format

- Industry 4.0 ready

- Up to 7 years data storage memory

- Multilevel password